Additive Manufacturing

KAIROS provides advanced Additive Manufacturing (AM) design and development support services. This includes performing advanced material research for characterizing AM part performance and predicting failure modes as well as, developing and producing cutting edge KAIROS’ Three-Dimensional (3-D) printers. A brief overview of our AM capability is shown in the tabs below. We have the strong industry and academic partnerships necessary to advance AM research and technology, built on an extensive pedigree of defense aviation experience.

KAIROS partners with Commercial, Civilian, and National Defense partners to solve the critical risk areas which are hindering mission success.

If you are interested in purchasing KAIROS Additive products or services, visit us at www.kairosadditive.net.

About our 3-D printing

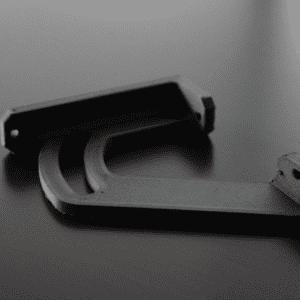

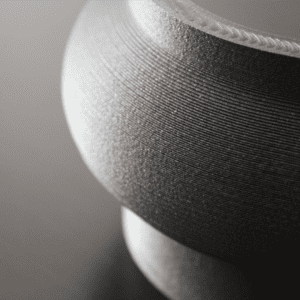

KAIROS Additive has developed our own Fused Filament Fabrication (FFF) 3-D printing Systems, the CL1720 and the CL3450. These scalable advanced systems utilize a wide range of thermoplastic materials—including fiber-reinforced thermoplastics that rival the strength of metals—to quickly produce strong, reliable parts that are accurate within microns. The systems are complemented by a platform of features that empower the user with the capability to easily manufacture parts.

We also provide Subject Matter Expertise to NAWCAD in the development of AM capability growth strategies, consultation on design and manufacturing of 3-D printed parts, and evaluation of 3-D printed parts. KAIROS is also currently deploying and supporting NAWCAD Field Technical Units (FTUs) which provide maintenance and sustainment support for ground mobile SOCOM platforms overseas. Our support enables manufacturing at the point of need which reduces cost and schedule challenges typically associated with inventory management. Additionally, in an effort to increase self-sufficiency across the islands, our systems are also being used in Hawaii to help improve sustainment and create jobs within the local Hawaiian community.

Systems

Superior speed and ~3 micron accuracy at a fraction of the cost of leading competitors. Open material system allows the use of any thermoplastic or brand. Able to use 26% more materials than leading competitors including PEEK and Ultem. Easy to use interface, optimized for a variety of thermoplastics including FDA and FAA approved materials. Open-source software (no annual license fees) Scalable Design. Mobile and self-contained 3D Model upload integration.

Services

Dedicated AM subject matter experts specialized in filament material selection to meet customer’s complex design requirements. Design engineering for AM including structural analysis, layup & parameter optimization, and material testing. for prototyping through functional use parts. Print services that can support 1 to 1000+ part production with the ability to print unique customer designs from a variety of material.

Training

Three-level “crawl-walk-run ” training available. Available onsite or in our classroom. Topics from how to set up the machine and manipulate settings to part optimization and material selection are covered in the curriculum.