Additive Manufacturing

KAIROS delivers advanced Additive Manufacturing (AM) design and development support services, including cutting-edge material research focused on characterizing part performance and predicting failure modes. Our capabilities extend to the development and production of KAIROS’ proprietary Three-Dimensional (3D) printers, engineered for high-performance applications. We maintain strong partnerships with both industry and academic institutions, enabling us to remain at the forefront of AM innovation. These collaborations are underpinned by our extensive background in defense aviation, positioning KAIROS as a trusted leader in advancing AM research, technology, and implementation.

KAIROS partners with commercial, civilian, and national defense organizations to address critical risk areas that hinder mission success—delivering strategic, actionable solutions that drive operational effectiveness.

If you are interested in purchasing KAIROS Additive products or services, visit us at www.kairosadditive.net.

About our 3-D printing

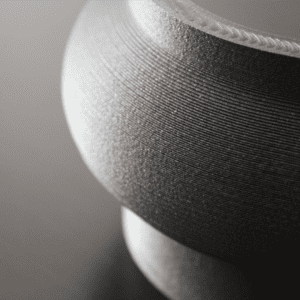

KAIROS Additive has developed its own line of advanced Fused Filament Fabrication (FFF) 3D printing systems—the CL1720 and CL3450. These scalable systems support a wide range of thermoplastic materials, including fiber-reinforced thermoplastics with strength comparable to metal. Designed for precision and durability, they produce high-quality parts with micron-level accuracy and are supported by an intuitive platform of features that empower users to manufacture components quickly and efficiently.

In addition to our technology development, KAIROS provides Subject Matter Expertise to NAWCAD, supporting additive manufacturing (AM) capability growth strategies, offering consultation on 3D part design and production, and evaluating printed components for performance and reliability.

KAIROS is actively deploying and supporting NAWCAD Field Technical Units (FTUs), which deliver maintenance and sustainment services for ground mobile SOCOM platforms overseas. Our solutions enable manufacturing at the point of need, significantly reducing the cost and delays associated with traditional inventory management.

Moreover, our systems are being utilized in Hawaii to support local sustainment efforts and foster workforce development—creating jobs and enhancing self-sufficiency across the islands.

SYSTEMS

KEY ADVANTAGES:

High Precision & Speed

Delivers ~3 micron accuracy with superior print speed—at a fraction of the cost of leading competitors.Open Material System

Fully compatible with any thermoplastic or brand, giving users maximum flexibility and supply chain resilience.Expanded Material Capability

Supports 26% more material types than competing systems, including high-performance polymers such as PEEK and Ultem.User-Friendly Interface

Intuitive design optimized for a variety of thermoplastics, including FDA- and FAA-approved materials.Open-Source Software

No annual license fees—fully open-source platform reduces total cost of ownership.Scalable & Mobile Design

Modular, mobile, and self-contained system with integrated 3D model upload, supporting rapid deployment and field-ready use.

.

SERVICES

ADVANCED AM EXPERTISE:

Dedicated AM Subject Matter Experts

Our team includes specialists in filament material selection, ensuring alignment with even the most complex customer design requirements.End-to-End AM Design Engineering

We provide comprehensive design support, including structural analysis, layup and parameter optimization, and material testing—from prototyping to functional-use parts.Scalable Print Services

Capable of producing 1 to 1,000+ parts, our print services support unique customer designs across a broad range of materials, tailored to meet mission-specific demands.

TRAINING

THREE LEVEL “CRAWL-WALK-RUN” TRAINING

KAIROS offers a structured, three-tiered “Crawl-Walk-Run” training program, designed to build foundational through advanced skills in additive manufacturing.

Flexible Delivery Options:

Training is available onsite at customer locations or in our dedicated classroom facilities.Comprehensive Curriculum:

Topics include:Machine setup and configuration

Settings manipulation and optimization

Part design and performance tuning

Material selection and application strategies

This hands-on program equips users with the knowledge and confidence to operate, optimize, and innovate using advanced AM technologies.